That's the small building in the center of the photo on top. Built in the 30s, it operated until the early sixties. Afterwards, the company next door purchased the property to use as storage. Below you can see it's not big, but we didn't want to fill up a 5000 S building with tools and equipment. This building will keep us honest, and it's in a price range that doesn't require us to rent out indoor space to people we don't know.

The whole lot gets amazing sun and the only neighbor over one story is just to the east, visible in the picture above. The interior is four areas. One "social" area behind the glass block, about 12' x 18' and the work area has three bays. The one behind the big door on the right is the auto bay. It's 13' wide and 20' long with 13' ceilings. The forge bay is behind the 10' x 10' door on the left side. It's also about 13' x 20'. Then there's a room joining them that's 16' x 24' where we'll have the common metal work area. There's a small room for welding and sandblasting and a bathroom and utility closet too. A lot of building in a small package.

Using extremely* elementary retouching techniques, I've tried to convey the way the building will look after the exterior masonry is complete.

*For best results, squint.

Fast forward to May, 2004.

Now when we leave the shop we can lock it down like a vault. The next thing on our wish list for the exterior is an awning that runs from the west overhead door to the right side of the large glass block window. We'll try to get to that this summer.

We needed our address on the building to help get our mail delivered, so we sat down and made up and address sign. Actually, Chris came up with a perfect design and there was no place to sit, so that's just a figure of speech.

Here Chris is utilizing the lift to put new brake lines on his Landcruiser.

The southern light is excellent for working under the truck when it's in the air.

The forge side of the shop with the overhead door closed. The anvil is a Hay Budden #258. It came out of a paper mill in Detroit, of all places, as did the giant vice in the background.

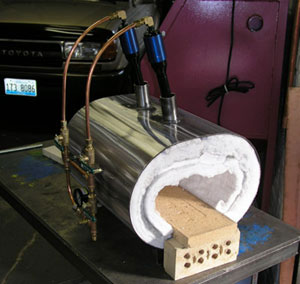

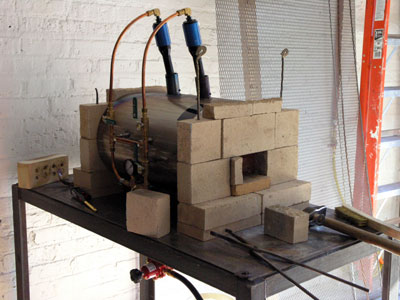

On the right is a closer view of the forge. It has two T-Rex burners by Rex Price. The forge shell and gas supply kit was provided by Jay Hayes.

The front and rear openings of the forge will be blocked off with firebrick for flexibility.

This is what the forge looks like with it's bricks in place. Not sure that this will be the permanent forge, but I'm happy with it so far.

That picture was taken over two years ago, I'll try to get a newer "used" image soon.

To make some hammers and to re-fit handles to old hammers and tools, one needs a few hickory handles. These followed me home from an auction in June. About a hundred I'd guess. I could get firewood and make them myself, but the price was too good to pass these up. Now I have to get started on some hammer heads.

Johnny

the friendly guard dog keeps an eye on the shop and it's surroundings.

He's pretty serious about his job.

Johnny

the friendly guard dog keeps an eye on the shop and it's surroundings.

He's pretty serious about his job.

It's always nice to have visitors. That's my sister Nancy and her Husband Steve and my wife Lisa.

The new anvil is a #378 Arm and Hammer serial number 48459, which dates it's manufacture to 1941-1945. It was made in Columbus Ohio by the Columbus Forge and Iron Company.

The chain around the anvil helps silence the ring. This anvil really rings loudly without the chain. Even with the chain, hearing protection must be worn when forging on this and most any other anvil.

Another guest, Mike Duchaj came over and made some hooks for his shop. He brought Sophie who entertained us.

The hammer rack keeps the heavy stuff handy for when the iron is hot.

Its made from an old out feed roller with the rollers removed and a grid

of 3/8 inch rod welded together. I hope the base holds up! If it doesn't

I hope it falls away from where I'm standing.

In early August I drove down to Texas to pick up a swage block from a nice man who had some Blacksmithing tools to sell. The trip was less than 48 hours but resulted in